Plant and

Equipment Builder

Tasks and Responsibilities

Plant and Equipment Constructors manufacture individual devices as well as complete systems and installations from metal. They produce the individual components and assemble them. Often, they accompany a product from planning through to final assembly.

A wide range of products is created in plant and equipment construction: machine housings, industrial boilers and piping systems, steel beams, climate and heating system components, entire railway cars, kitchen installations, elevators, and more.

Plant and Equipment Constructors often follow a product through all stages of its development, from project planning through manufacturing and final assembly to commissioning. They are usually also responsible for the subsequent maintenance and repair of the systems.

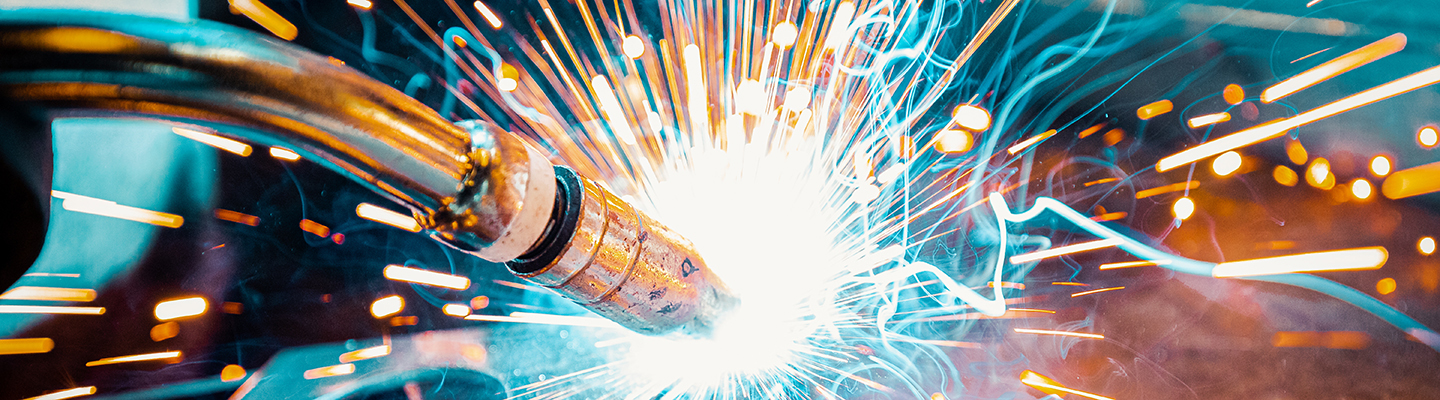

The primary material they work with is metal. They master all separation, forming and joining techniques required for its processing. Based on technical drawings, they punch and cut sheet metal to the required dimensions and shape it through bending and folding. Together with partially or fully prefabricated components such as profiles and pipes, they assemble systems and devices. For joining, they use techniques such as screwing, riveting, soldering, and welding. They work with both hand tools and computer-controlled machines, which, for example, automate welding processes or cut sheet metal using laser or water-jet technology.

In plant and equipment construction, workpieces can be as large as a single-family house. Despite their size, constructors must process components with high precision to ensure smooth assembly. Accurate planning of work processes is essential. In doing so, Plant and Equipment Constructors ensure compliance with safety standards for personnel, machinery, and the environment.

Most work is carried out in manufacturing halls. Final assembly, however, often takes place on-site at the installation location. They usually work in teams and closely with other specialists such as design engineers or automation technicians.

Additional tasks may include creating technical documents and quotes, procuring materials, or performing quality control checks.

Apprenticeship

Duration

4 years

Practical Training

In a company within the machinery and metal industry. During the first two years, basic and supplementary training is provided. In the 3rd and 4th years, specialized training is offered in at least two areas of the company’s operations.

School-Based Education

1–2 days per week at the vocational school. Job-related subjects include: technical fundamentals (mathematics, computer science, learning and work techniques, physics, electrical and control engineering, technical English), materials and manufacturing technology, drawing and machine technology, and supplementary courses in process engineering. Inter-company courses cover a variety of topics. Students with excellent academic performance may attend the vocational baccalaureate school during their basic training.

Qualification

Federal VET Diploma «Plant and Equipment Constructor EFZ»

Requirements

Educational Background

- Completed compulsory schooling

Skills and Competencies

-

Manual dexterity

-

Practical understanding

-

Spatial imagination skills

-

Technical understanding

-

No allergies to metals, greases, or oils

-

Teamwork skills

-

Ability to work independently