Production

Mechanic

Tasks and Responsibilities

Production Mechanics manufacture and process components made of metal and plastic. They assemble parts into modules and perform maintenance on devices, equipment and machines.

Production Mechanics work in mechanically and technically oriented companies. There, they process metals, sheets and components. They assemble these components into devices, equipment and machines. For this purpose, they read manufacturing documents and technical drawings and prepare the necessary tools and equipment. They carry out their tasks and projects accurately and independently, sometimes in a team and together with other specialists.

Primarily, Production Mechanics work with metals such as steel, stainless steel or aluminium, but they also work with plastics. They master various processing and joining techniques: drilling, turning, milling, grinding, shearing, bending, edging and punching. They also screw, solder, rivet and weld components. Using modern automatic lathes, they produce precision parts, for example for the watch industry, and they process circular saw blades or other tools on grinding machines.

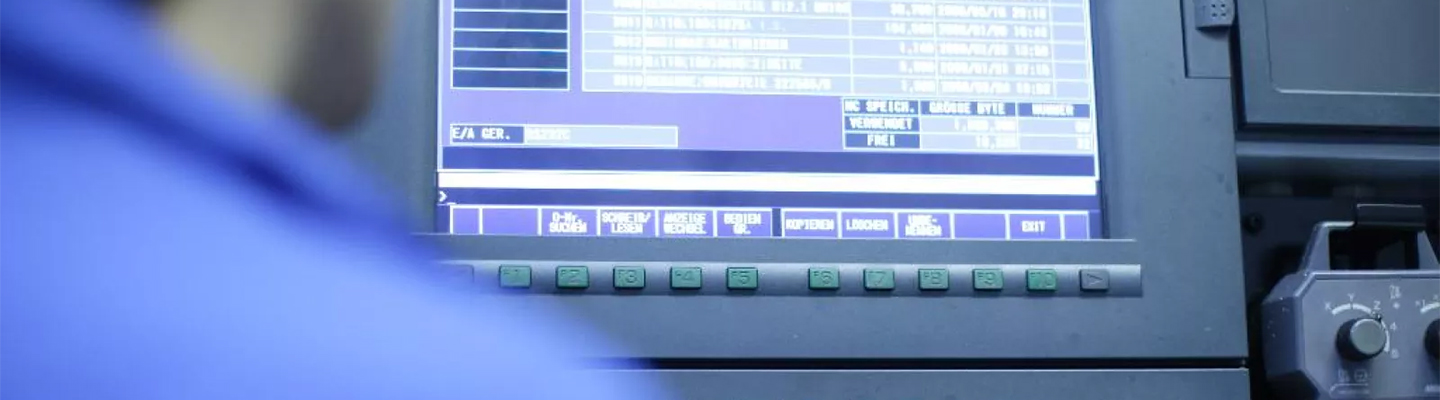

Production Mechanics manufacture device, equipment and machine parts or entire steel constructions from metal or plastic. They continuously monitor series production on computer-controlled machines such as laser or water jet systems and intervene when necessary. If deviations occur, they adjust the production machines. They also produce precise individual components on lathes and milling machines. Some parts are treated with heat to harden them and make them resistant to wear. Their responsibilities also include computer-controlled tool sharpening. After production, they check the quality of parts using measuring instruments.

Production Mechanics assemble and install individual components into modules. They build devices, equipment and machines of various sizes, from very small units such as medical pumps to large systems requiring lifting equipment. They inspect, improve and maintain finished machines. If necessary, they disassemble machines and replace individual mechanical, pneumatic or hydraulic elements. Throughout their work, Production Mechanics adhere to applicable safety regulations. For example, they wear gloves and protective glasses while welding, ensuring both their own health and environmental protection.

Apprenticeship

Duration

3 years

Practical Training

In a company within the machinery, electrical and metal industry (MEM industry). During the first two years, basic and supplementary training is provided. Specialized training in at least one area of the company’s operations is delivered over the three-year apprenticeship, depending on the company’s possibilities as well as the interests and abilities of the apprentices.

School-Based Education

1 day per week at the vocational school. Job-related subjects include: technical fundamentals (mathematics and physics), materials technology, drawing techniques, joining, manufacturing and machine technology. Inter-company courses focus on practical learning and the development of professional skills. Students with excellent academic performance may attend the vocational baccalaureate school during their basic training.

Qualification

Federal VET Diploma «Production Mechanic EFZ»

Requirements

Educational Background

- Completed compulsory schooling, basic or middle school level

Skills and Competencies

-

Interest in technical systems and processes

-

Practical understanding

-

Technical comprehension

-

Spatial imagination skills

-

Strong manual dexterity

-

Enjoyment of working manually and with machines

-

Accurate and careful working style

-

Teamwork skills

-

Reliability